PositionHome > PRODUCTS & SOLUTIONS > Wellan2000 Water Ring > text

WELLAN2000

With proper installation, every WELLAN2000 water ring woks efficiently to prevent buildup of scale, stop corrosion and combat biofilm and microorganism

Scale

Calcium carbonate in dissolved form is contained in virtually all water. Calcium carbonate only becomes a problem if it is precipitated and deposited on surfaces. This occurs for two reasons. "Normal water" loses its ability to bind calcium carbonate upwards of temperatures of 30°C. The ability to bind the calcium carbonate drops continuously as the temperature increases and the calcium carbonate is precipitated. The second essential reason for the deposits is when water evaporates. Minerals dissolved in the water, such as the calcium carbonate, are unable to evaporate and are left behind. This phenomena leads to scale being deposited in machines and pipes, primarily if they operate at high temperatures, and this scale is deposited on the surfaces. If suitable measures are not taken, the pipes or heat exchangers frequently clog up after a very short time.

The water pressure drops more and more until, ultimately, virtually no water is able to flow. Consequently, water is chemically pre-treated, primarily in the case of critical applications. This is a relatively expensive procedure since costs are incurred for chemicals and servicing on the machines. In many applications, a great deal of water is consumed so that it makes very little sense economically to pre-treat this water and a decision is taken to accept the need to descale heat exchangers etc. from time to time.

WELLAN represents a very good-value-for-money alternative to the above procedures. The oscillations emitted into the water by the WELLAN rings change the structure of the calcium carbonate on a sustained basis. This means that the calcium carbonate can be bound far better by the water and is thus precipitated only at far higher temperatures. If the flow in the pipe or the machine is adequate, the scale is entrained by the water. If the flow rate is low or too low, scale with a soft, grimy consistency may be left behind. This can then be removed mechanically very easily without the use of chemicals. Very good experience is available from operators of several heat exchangers worldwide, some of them with capacities exceeding 1,000 m3/h.

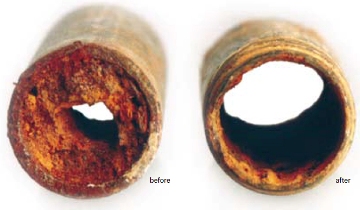

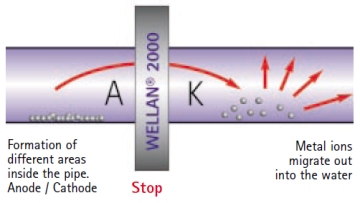

Corrosion

Water has many characteristics and properties. Thus, water, in unsaturated state,is amongst the most aggressive fluids in existence and attacks metals quite particularly. This leads to corrosion. Even stainless steel of optimum quality is not immune to such corrosion. Many types of corrosion and reasons for such corrosion are known. It can be assumed that WELLAN stops and reverses the simple forms of corrosion, i.e. corrosion owing to stagnant water and unsaturated water (water with a low mineral content). In the case of corrosion owing to galvanic elements, creepage currents, acids and lyes etc., it is generally able at least to slow down corrosion. However, in some cases, such forms of corrosion have been completely stopped. The oscillations of the WELLAN rings convert the rust or, to be more precise, influence the iron ions. These iron ions are detached from the rust. Thus, over the course of time, existing rust is detached and is flushed out. When the existing corrosion has been removed, the inside of the pipe becomes black over the course of time. This means it is coated with a saturated iron oxide coating (magnetite, Fe3O4). This black protective coating no longer offers the rust the possibility of reforming.

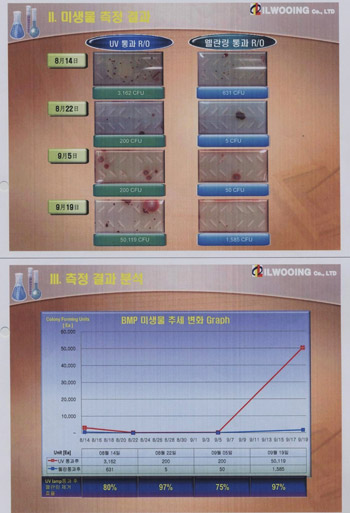

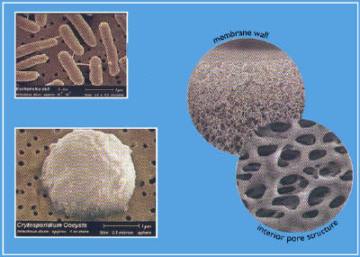

Biofilm, bacteria

In many systems, deposits attributable to microorganisms are formed. The origin of these deposits is debatable and it must be assumed that they are generally entrained from the outside. These microorganisms, once they are in the system, propagate and frequently spread throughout the entire system and form a film on the pipe walls. This film is considered as a form of corrosion, primarily because some of these microorganisms emit secretions which are very aggressive and which attack the pipes. The bacteria emit spores in the biofilm or other deposits, and these spores can be removed only with great difficulty. In such cases, thermal and chemical methods frequently reach their limits since it is very difficult to kill all spores during the rehabilitation process. However, we shall not discuss this problem in greater detail at this point. There are study and research groups, for example at the DECHEMA, which devote their attention solely to this topic. WELLAN technology has developed special units for this problem. Good successes have already been achieved in such cases on a small scale. On this subject, we are constantly seeking installations for practical tests.

thermal and chemical methods frequently reach their limits since it is very difficult to kill all spores during the rehabilitation process. However, we shall not discuss this problem in greater detail at this point. There are study and research groups, for example at the DECHEMA, which devote their attention solely to this topic. WELLAN technology has developed special units for this problem. Good successes have already been achieved in such cases on a small scale. On this subject, we are constantly seeking installations for practical tests.

To summarize all applications, our WELLAN products have the following main features:

Innovative Technology

Eco Friendly

No Chemical Additives

Reduced Operating Costs

Potential Future oriented

Cost Effective

Technical Parameters

| Pipeline Material | Not limited, applicable to all types of material |

| Effective Work Distance | 3.5 km downstream of installation point |

| Upper Limit of Temperature | 150 |

| Lower Limit of Temperature | -50 |

| Non-circulating Throughput | 15000 cm/hr |

| Circulating Throughput | 120000 cm/hr |

| OD of the Pipeline | 12mm ~ 2000mm |

| Usage Life | >15 Years |

Maintenance costs of WELLAN products: ZERO.