PositionHome > PRODUCTS & SOLUTIONS > Wellan2000 Special Ring > text

WELLAN®2000

Oil and water pipelines above ground

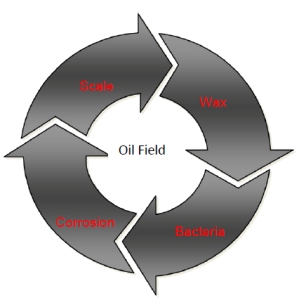

As petroleum products including natural gas are produced, salt and water molecules cause scale build-up that puts additional stress on the production equipment and corrosion that leads to premature failure of production equipment. In addition, during long transport process, bacteria such as SRB, IB etc. grow. Secretion from such bacteria is acidic that exacerbates corrosion situation. Wax in the state of liquid at high temperature begins solidifying and depositing on the inner wall of transport tubes and pipelines. After some time the pressure goes up and flow rates go down along all the pipelines and choking and leaking may occur at some critical parts. The whole transport system will soon be paralyzed.

In many oil fields, WELLAN®2000 has been successfully applied to solve such problems, saving billions of dollars for customers. In the market of China, our products have witnessed outstanding performance by reducing the corrosion rate by as much as 96%.

The most appropriate down-hole tool for wax cleaning

Wellan2000 Special Ring is an effective device used in underground oil production well for prevention and removal of scale, paraffin and asphalt deposition which usually build up inside oil pipes. When installed in an oil production well, current treatment methods such as wireline scraping, chemical and or hot oil circulation, can be significantly reduced or completely eliminated. The tool simply comprises three parts: the central function ring, and the protective locking rings on both ends of the central ring. Locking rings are anchored to both ends of the central ring around the tubing as tightly as possible to prevent movement of the central ring.

WELLAN2000 down-hole tool represents the newest solutions for your paraffin and corrosion problems!

Our Standard WELLAN2000 down-hole tools are ideally suited for new completions and scheduled workers. The tools can be installed above or below the pump or as a tail joint(s). The ultra-fine oscillations emitted by the tool stabilize the water-in-oil emulsion structure and prevent the paraffin being released from the micelle structure and forming solid states. This means less viscous oil at surface resulting in:

- increased pump life and efficiency

- reduced operating costs and workovers

- increased oil production and stability

For Scale and Corrosion problems, with WELLAN2000 down-hole tools installed, scale and corrosion will be eliminated or significantly reduced, resulting in:

- improved production equipment efficiency

- prolonged production equipment life

- less downtime